Where To Buy Febco 765-1 Repair Kit

Febco PVB Bonnet/Poppet Kit i in. - 1-one/4 in. | FE905-212

Sales Price $64.39 Our Cost $91.95 Y'all salve 30%

Febco PVB Bonnet/Poppet Kit 1 in. - 1-1/four in.

The Febco FE905-212 is the replacement bonnet and poppet kit for Febco i - 1-one/iv inch pressure vacuum billow assemblies.

- Febco Bonnet & Poppet Kit

- Fits a 1 inch to 1.25 inch Febco Pressure level Vacuum Billow

- Compatible with FE765-100

Features & Benefits

FEBCO is so confident of the heavy-duty structure and "freeze plug" design of the Series 765, it is the only manufacturer to offer a lifetime warranty on the bronze valve torso of the i⁄2" through 11⁄four" models*. In most pressure level vacuum billow designs, the statuary torso tin split open when water inside expands in freezing temperatures. When this happens, the whole unit must exist replaced which can be expensive and downright inconvenient. But should an unexpected freeze take hold of your irrigation system.

Series 765 Pressure level Vacuum Breaker Features: Just FEBCO offers a Lifetime Warranty on the bronze body of the 1⁄2" through eleven⁄4" Series 765.

The sectional "freeze plug" design characteristic of the 1⁄two" through xi⁄four" models prevents freeze damage to the bronze body and limits impairment to less expensive internal components. Unique cheque valve blueprint reduces check valve fouling and chattering providing longer life and more than reliable operation.

Vandal/tamper resistant contumely canopy and test cocks mean problem-free performance. Engineered plastic and brass internal parts resist chemical and mineral eolith build-upwardly for more reliable performance. Heavy duty engineered plastic poppets provide reliable operation.

Product Details

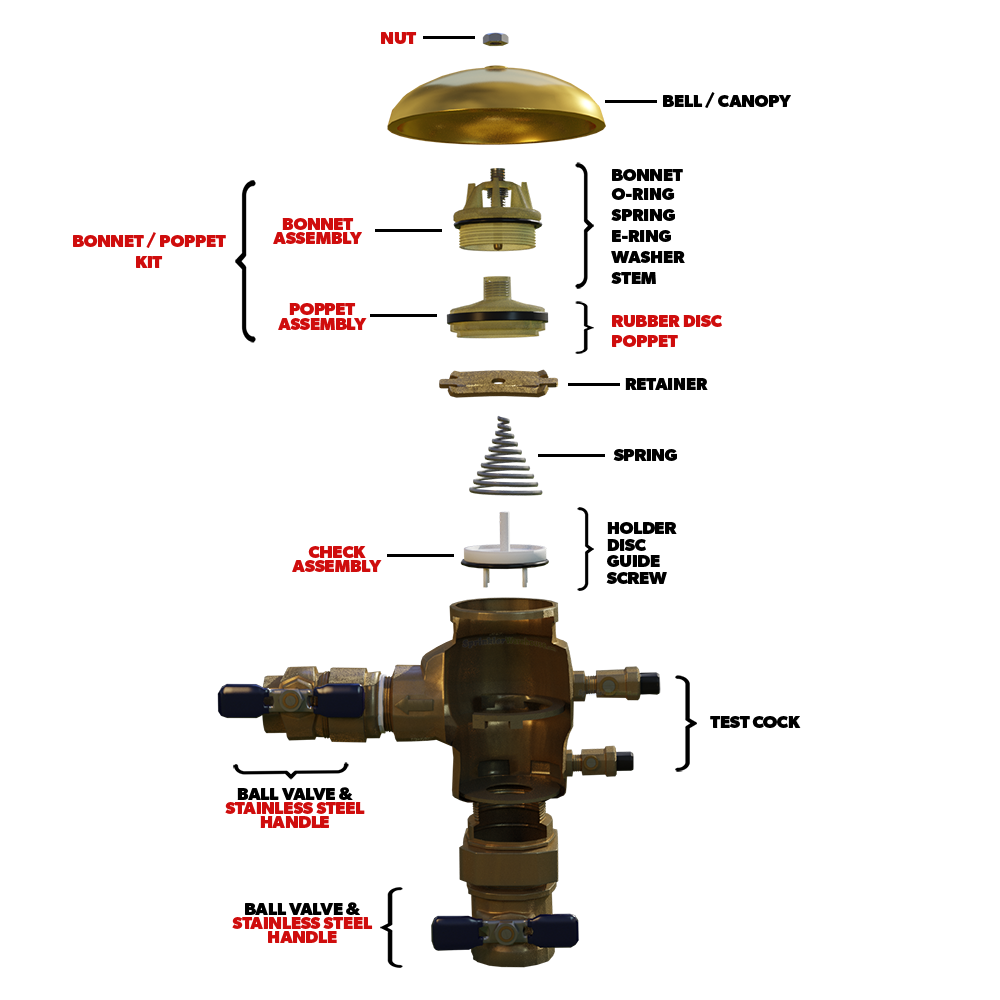

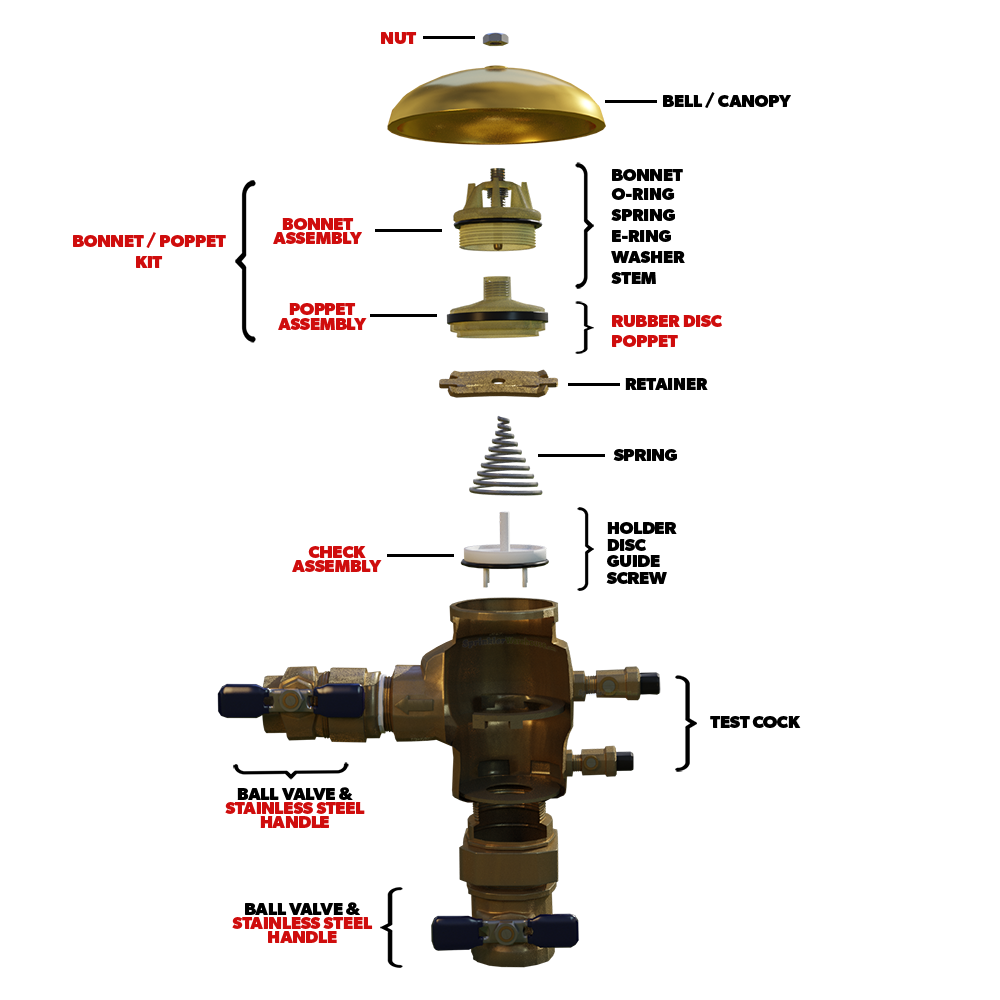

Here are 2 Ways to Make up one's mind the Size Kit Y'all Need:

- Measure beyond the lesser of the Poppet (item 12 in picture above); the distance across the bottom of the Poppet will determine which size kit you need:

- 1/2" & 3/iv" Kits: Poppet measures 1- one/8" to ane- 3/16" across the lesser (diameter).

- 1" & 1-1/four" Kits: Poppet measures ane- seven/8" beyond the lesser (diameter).

- one-1/2" & two" Kits: Poppet measures 3- 7/16" across the bottom (bore).

- Mensurate across the lesser of the Bonnet Associates; the distance beyond the bottom of the Bonnet Assembly (threaded office) will make up one's mind which size kit you need:

- one/2" & 3/4" Kits: Bonnet Associates measures i- 5/16" across the bottom (diameter).

- one" & 1-1/iv" Kits: Bonnet Associates measures ii- 3/sixteen" across the lesser (diameter).

- ane-ane/2" & two" Kits: Bonnet Assembly is made of brass and measures 5- 1/viii" across the bottom (diameter).

| Symptom | Crusade | Solution |

| 1. Bank check valve fails to concur 1.0 PSID minimum | A. Droppings on sealing surface or guide surfaces valve surfaces B. Damage seat disc C. Weak or broken spring D. Poppet broken due to thermal expansion | A. Disassemble and clean cheque B. Disassemble and replace seal C. Disassemble and replace spring D. Supersede cleaved poppet |

| 2. Poppet fails to open at 1.0 PSIG minimum | A. Debris restricting free operation B. Poppet seal adhering to bonnet C. Weak spring load | A. Disassemble and clean check valve surfaces B. Detach and make clean and/or supplant damaged parts C. Supervene upon bonnet assembly (1/two - 11/iv) |

| iii. Minor leakage through air vent | A. Damaged poppet seal B. Cracked or damaged poppet C. Cracked bonnet or damaged sealing edge D. Debris on sealing surface | A. Detach and supercede seal B. Disassemble and replace poppet seal C. Disassemble and replace bonnet assembly D. Disassemble and clean |

| 4. Significant discharge through air vent | A. Poppet not properly guided B. Major poppet or seal failure C. Low downstream pressure D. Bereft inlet volume to operate device E. Poppet and or bonnet broken | A. Disassemble and replace damaged parts B. Disassemble and supercede damaged parts C. Bank check pressure at #ii testcock; should be higher than 5 PSIG if low system D. Force per unit area needs to be increased or partially closed outlet brawl valve to create college pressure on poppet. E. Replace broken bonnet/poppet due to thermal expansion (run into freeze protection) |

| five. Chatter during flow conditions | A. Worn, damaged or defective bank check valve guide | A. Disassemble and repair or supplant guide |

*Cherry indicates repair parts sold at the Sprinkler Warehouse

How to Supercede the Bonnet and Poppet (you should always alter both):

- Turn off the h2o supply(Warning: Failure to Clinch the H2o Pressure is Relieved can cause Damage!)

- Close water supply side ball valve outset

- Go to the sprinkler controller and manually start each zone or section valve by manually starting the sprinkler system. This volition relieve the water force per unit area in the PVB. Then plough off the manual performance of the sprinkler organization.

- Close 2d ball valve (on outlet side of PVB)

- Make sure that you have relieved water force per unit area by opening test cocks on side of PVB

- Place large O-Ring (included in kit) around Bonnet

- Apply lubricant (included in kit) to gasket

- Fit (slide it onto) Poppet on brass guide stem of Bonnet

- Thread Bonnet into PVB unit (hand tight merely)

- Supercede Canopy and tighten nut on superlative of awning using a wrench

- Plow on the h2o supply

- Open up h2o supply side ball valve showtime and rapidly

- Open 2d ball valve

90% of the Pressure level Vacuum Breakers (PVB) installed for a typical residential home are 1" PVB'southward

Kit 905-211: includes the Bonnet and Poppet Assemblies for both one/2" and 3/iv" Pressure Vacuum Breakers

905-212: includes the Bonnet and Poppet Assemblies for both 1" and i 1/4" Force per unit area Vacuum Breakers

Repair Parts For A Febco 765 1 or i ane/4 in. Backflow Preventer Including The Bonnet And Poppet

Everything Needed To Repair a Febco 765 At Sprinkler Warehouse

The FE905-212 Febco Repair Kit includes a rubber O-band, bound, Eastward-ring, washer, stem, bonnet, and poppet. All parts are genuine and original to the valve. Requiring no special tools for the repair and installation process, this kit is a real lifesaver for your handbag and bank. Quickly gear up water spillage and waste with this wonderful product from Sprinkler Warehouse.

five Features Of The Repair Kit:

- All parts are fabricated of high-quality materials

- Mill replacement parts

- No special tools required for servicing

- Fits one and 1 1/4 inch pressure vacuum breaker

- Operable from 33°F to 140°F

How To Repair A Cleaved 765 Backflow With New Bonnet And Poppet Installation

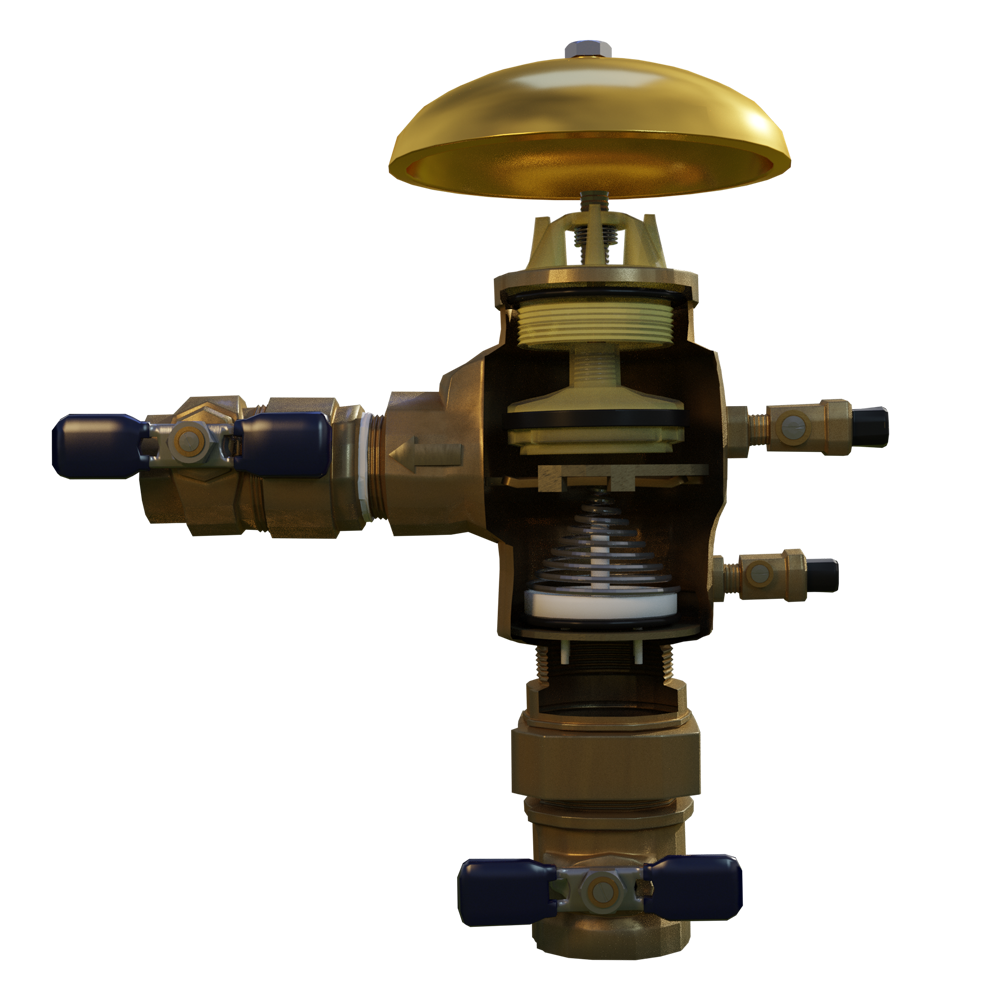

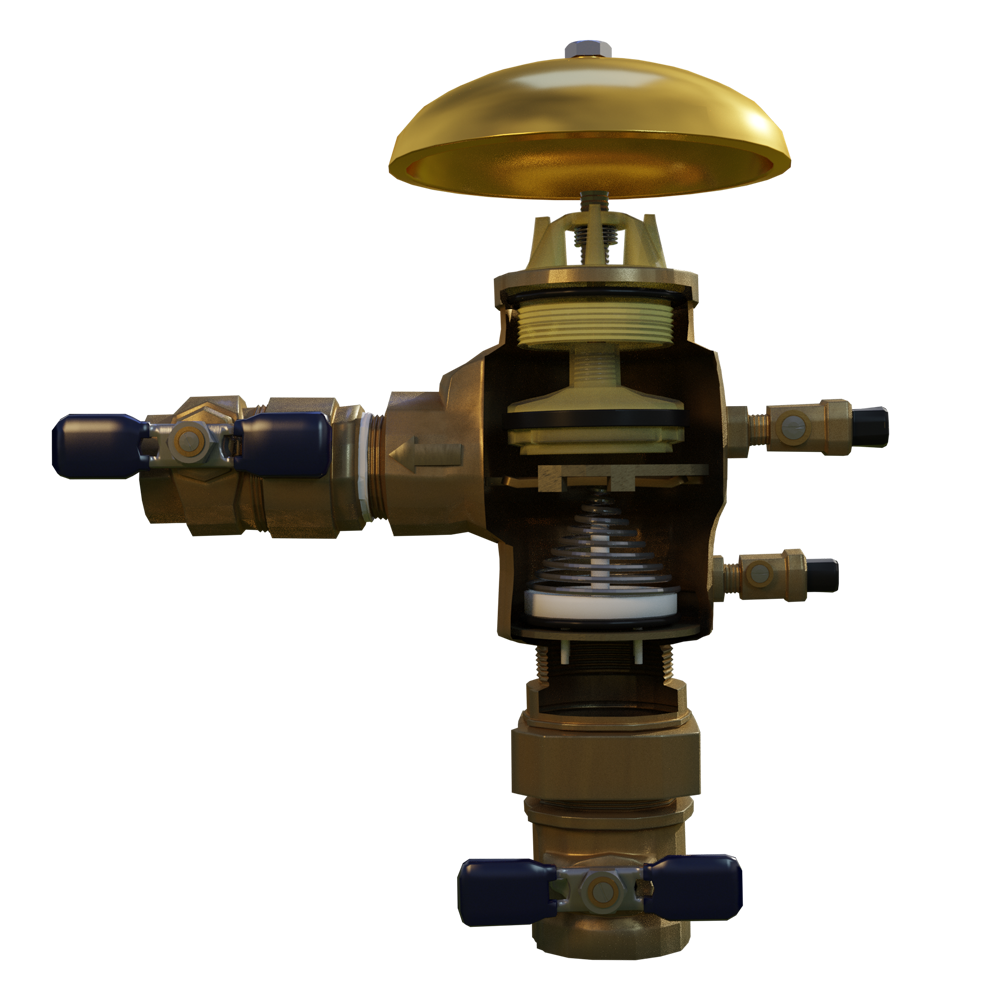

Pressure Vacuum Breakers are notorious for breaking under freezing weather conditions. Fortunately, 765s are made with a durable bronze body for extra freeze resistance and the bonnet and poppet come with unique freeze-plug technology for the all-time freeze protection available. In order to repair a broken 765 simply drain the torso, remove the cleaved interior pieces, and and then supercede the removed parts with the items in this kit.

Pressure Vacuum Breaker Repair Parts And Accessories For Auction

Exterior of the durable statuary torso of a 765 PVB, Febco offers unique and original product replacements for the interior components of the 765. The lightweight poppet seals the air in minimal flow scenarios, and all internal parts are serviceable from the elevation of the unit. The repair kits are like shooting fish in a barrel to employ, requiring no special tools, and comes with directions.

Repair PVBs Quickly For Quick Protection Confronting Contaminated Water

PVBs like the 765 are important for backflow prevention, as they protect drinkable h2o from contaminants that may be present in the irrigation organisation's internal h2o. This could lead to affliction or possibly, in extreme cases, death. PVBs will leak water from the height if they are not working, so information technology'south easy to place and fix the trouble. Purchase your repair kit now at Sprinkler Warehouse.

Frequently Asked Questions

How do yous ready a 765 1 in. PVB?

Turn off the water supply starting time. Next, turn off the inlet ball valve and open the test cocks. And then close the outlet ball valve. Remove the interior pieces from the 765, then place the O-Band effectually the bonnet. Fitt the poppet into the bonnet, and thread the bonnet into the PVB. Make sure to hand tighten only! Supervene upon the brass canopy and tighten the nut on elevation with a wrench. Turn on the water supply, and open the inlet valve first, then the outlet valve.

What size is my PVB backflow device?

The base of the poppet tin can be measured to decide what size your PVB is. If your poppet measures between 1 1/8" and 1 iii/16", so you have either a 3/iv or 1/two inch PVB. If your poppet measures 1 7/8" across the bottom so it's a i or one 1/4 inch PVB. And if you have one that measures 3 7/16" or over and so you lot take a 1 1/ii inch or larger PVB.

What does a backflow preventer await similar?

A pressure level vacuum billow backflow looks like a right-angle piece of bronze or other metal with a bell/canopy on top of the right bending. There are often two valves, 1 on each side of the joint in the device. The backflow is designed to prevent backsiphonage with minimum head loss.

| Brand | Febco |

|---|---|

| Series | Febco PVB Bonnet/Poppet Kit |

| Backflow Compatability | Febco PVB Repair |

| Warranty | one Year |

| Size | 1 in. - i-1/4 in. |

Nosotros found other products you lot might like!

Source: https://www.sprinklerwarehouse.com/febco-pvb-bonnet-poppet-kit-1-in-1-1-4-in-fe905-212

Posted by: salgadohawas1970.blogspot.com

0 Response to "Where To Buy Febco 765-1 Repair Kit"

Post a Comment